Mastering the art of Rolling Rings: A Deep Dive into Techniques and Traditions

- info3309277

- Jul 11

- 3 min read

When you think about metalworking, the rolled rings process stands out as a captivating blend of science and craftsmanship. This method shapes metal into rings that are essential in many industries. Whether you are a professional, an engineering enthusiast, or just curious, grasping the evolution and details of the rolled rings process will deepen your appreciation for this craft.

The rolled rings process has become a vital manufacturing technique across various sectors, including aviation and oil and gas. Rolled rings offer unmatched durability and precision that other manufacturing processes struggle to achieve, making them a popular choice.

What is the Rolled Rings Process?

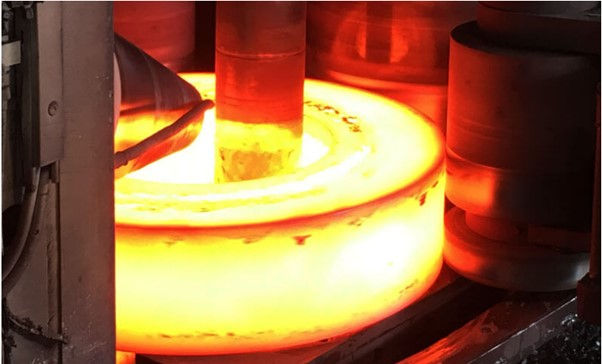

The rolled rings process, also known as ring rolling, involves turning a solid metal billet into a ring by applying pressure. It starts by heating a round metal piece until it becomes malleable. Specialized ring rolling machines then use rollers to shape this heated component into its final ring form.

Rings produced can vary greatly in diameters and thicknesses. For instance, they may range from small parts of just a few mm wide to large components exceeding 2000mm in diameter. The goal is to create rings robust enough to handle extreme conditions, like those found in aerospace applications or high-pressure environments in oil drilling.

The Basics of Ring Rolling

The ring rolling process comprises several crucial steps:

Preparation of the Billet: The first step involves selecting the right raw material. Common choices include steel, stainless, and various alloys. Each material is chosen based on specific mechanical properties needed for the final product.

Heating: The selected billet is heated in a furnace to a temperature that optimizes its malleability. This step can significantly enhance the material's ability to be shaped without cracking.

Rolling: Once heated, the billet is placed in a ring rolling mill. The rollers compress the billet to form it into the desired shape. This stage is vital because it determines the ring's final dimensions and tolerances.

Heat Treatment: After rolling, the newly shaped ring undergoes a heat treatment process, which ensures stability in its properties.

Finishing: Finally, the ring may go through additional processes like machining or surface treatments to prepare it for its intended use.

Following these steps, manufacturers can produce rolled rings that meet strict requirements across various industries.

Advantages of the Rolled Rings Process

The rolled rings process provides numerous benefits that make it a standout choice in many fields:

Material Efficiency: This method produces significantly less waste compared to traditional forging techniques. For example, waste can be reduced by up to 20%, leading to cost savings and less environmental impact.

Strength and Durability: Rolled rings have excellent mechanical properties. This makes them perfect for high-stress applications, particularly in aerospace. For instance, aircraft components like turbine disks must endure high loads while remaining lightweight.

Versatility: The process can create an array of ring sizes and thicknesses, making it adaptable for various projects.

Applications of Rolled Rings

Rolled rings are widely used across various industries due to their robust characteristics. Here are some key applications:

Aerospace: In aircraft engines, rolled rings are crucial for structural integrity. For instance, they are used in engine components that must withstand extreme temperatures and pressures.

Oil and Gas: This sector relies on rolled rings for equipment like downhole tools, which need to endure massive pressures often exceeding 10,000 psi.

Energy: In renewable energy, rolled rings are essential in wind turbine gear systems, where durability is critical for performance and maintenance.

The strength and adaptability of rolled rings make them essential to contemporary engineering solutions.

The Future of the Rolled Rings Process

As industries advance, so too will the rolled rings process. Innovations in materials science and manufacturing technologies.

As sustainability takes centre stage in manufacturing, the rolled rings process may adopt greener technologies. This could further increase its appeal in an era where environmental considerations are paramount.

Would you like to learn more - contact us @ info@progressivemetals.co.uk

Comments